An upstate New York paper mill suddenly had the sprockets and bushings of its large debarking machine spin onto one of the rotating shafts. This left the paper mill with the unfeasible choice of paying an exorbitant price to ship the large shaft to a repair facility, not to mention the impending downtime and revenue loss.

As soon as we heard of the paper mill’s dilemma, we immediately sent our portable machining services to repair the large rotating shaft. Our on-site machining services rose to the occasion, completing the repair and reassembly in one weekend.

On-Site/Portable Machining Capabilities

Our fully trained technicians made time-sensitive repairs to the paper mill debarking machine by implementing the necessary portable machining capabilities we offer. Our capabilities include:

Flange Facing

Our machinists specialize in machining full face, raised face, back face, and grooved flanges for smooth flange repairs that prevent leaks from damaged or deteriorating flanges. Also, we offer rugged internal and external mounted machines up to 120” O.D.

Our flange facers allow for a large selection of cuts, including O-ring grooves, vertical grooves, V-grooves, pipeline flanges, and reactor vessel flanges. We produce high-precision and smooth finishes, increasing the service life of the equipment.

Pipe Cutting / Weld Preparation

On-site pipe cutting applications and weld preparation deliver expeditious cutting, repair, and removal of corroded pipe systems. Our expert team also prepares high-quality pipe joints for better welder efficiency, and alignment of pipes, valves, tubes, and vessels.

Shaft & Journal Machining

We perform precise repairs of worn and damaged journals and shafts up to 11” in diameter. Our portable machining also allows our operators to repair stepped profiles, ring grooves, and parallel shafts. In many cases, we remove weld build-up for corrosion resistance and offer on-site polishing.

Journal and shaft repair are major applications of our on-site services. Our technicians provide these services for mixer and roll journals, turbine rotor journals, fan shafts, alternator and ventilator shafts, crank pins, and pumps, returning them to serviceable condition.

Line Boring

Maximizing and fine tuning boring holes is our specialty. We enlarge and perfect bores on cylindric and flat surfaces. Our field-proven boring equipment ensures the alignment and accuracy on even larger bores. We service sizes from 1 – 36” diameter, and over 60” to 12′ between the bores.

We provide line boring solutions for industrial equipment and machining materials, such as bore repair of earthmoving and mining machinery. Our portable boring machines also conduct line bore honing for printing presses, pump housings, excavator buckets, valve bodies and seats, diesel engines, turbine casings, and crank and camshaft housings.

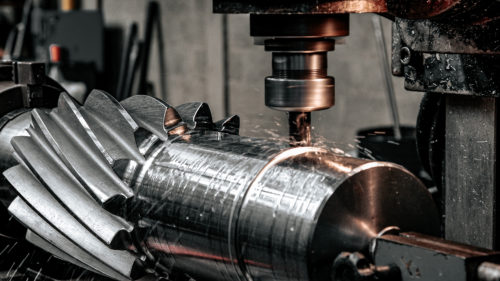

Milling

We use highly-calibrated, on-site milling machines for precise multi-axis machining. Our technicians can mill the cutting pump and motor bedplates, including heat exchanger division plates.

Services also include milling internal and external keyways for bores and shafts, as well as tracks and crane pedestals. We also offer milling for steel rolling, sinter plants, hatch covers, and square flange machining, concast units, blast and oxygen furnaces, iron ore terminals, fin and fan cooler join faces.

Marshall Industrial Technologies Brings On-Site Machining Solutions to Customers

Our team at Marshall Industrial Technologies met the challenge and used our on-site machining capabilities to get the NY paper mill debarking machine up and running in one weekend. As a leading provider of on-site machining solutions, our goal is to provide you with cost-efficient, timely service to keep your business running.

Contact us with any questions about our on-site machining services or request a quote today.